X system Workshop Concept Exhibition

R&D and Manufacturing as an Ecosystem

In July 2025, the first phase of CAMERICH (Jiaxing) Mega Factory was completed, marking the company’s formal establishment of a North-South layout. The Jiaxing Mega factory and the Beijing R&D campus will work in tandem with designers and the supply chain to explore future innovations for the brand. In May 2025, CAMERICH began collaborating with designer Mario Tsai on the modular X System product line.

In September 2025, at the 56th China (Shanghai) International Furniture Fair, the modular X System was launched. To present the development journey of the X System from scratch, CAMERICH invited Mario Tsai Studio and magazine into to co-curate the “X System Workshop” concept exhibition.

At the exhibition, the documentary "X System Workshop" was screened for the first time. The R&D for X System took place at Mario Tsai’s studio in Hangzhou, with ongoing collaboration with the CAMERICH R&D department, followed by trips to Foshan for supervision of the profile extrusion and die-casting processes. The final products were returned to the CAMERICH(Beijing) R&D Campus and will eventually be manufactured at the CAMERICH (Jiaxing) Mega Factory.

Director Xinqiao documented the scenes in Hangzhou, Foshan, and Beijing, illustrating the connections between regions, cultures, and individuals underpinning the product.

Starting with the X System

Exploring Innovations in Manufacturing Processes

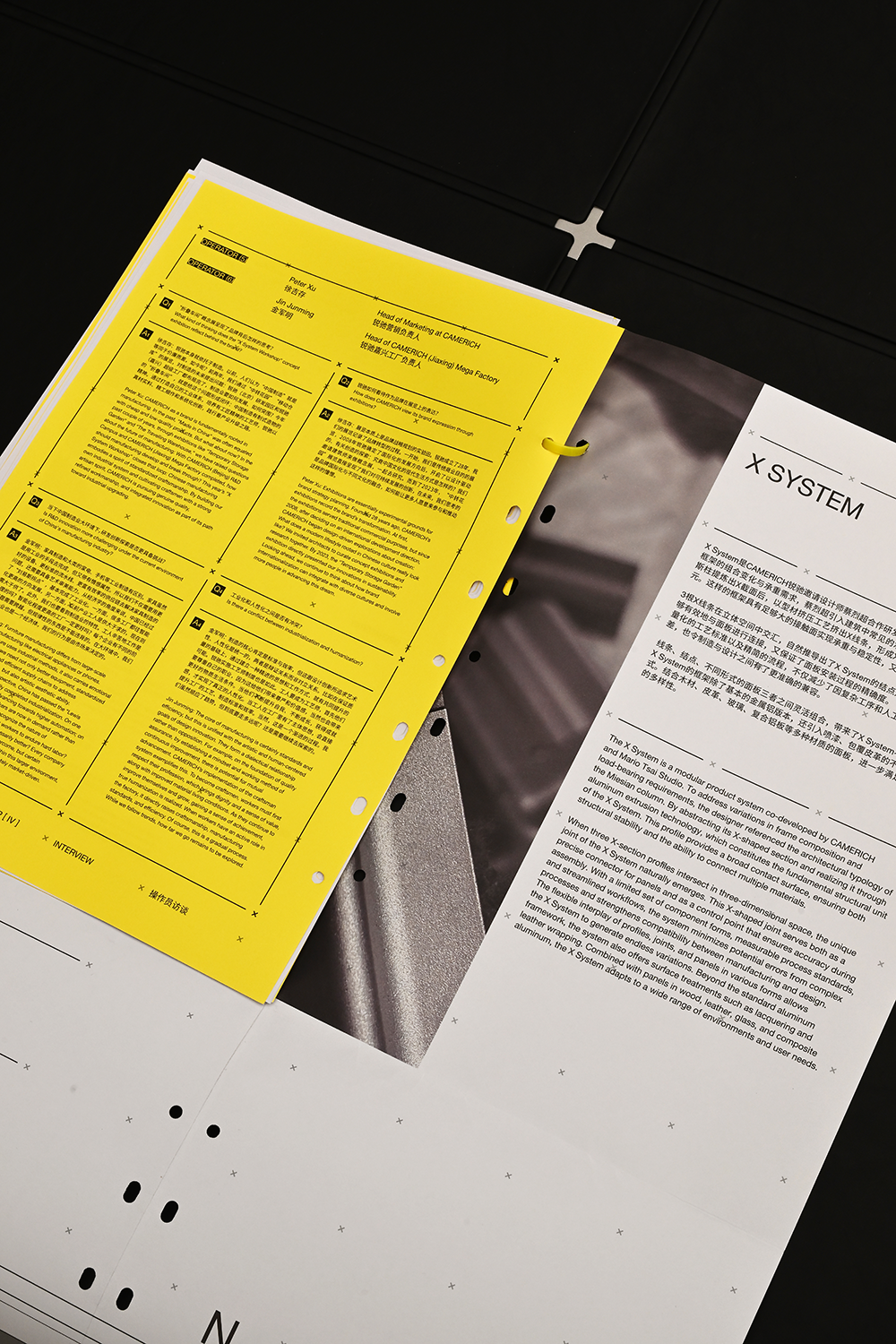

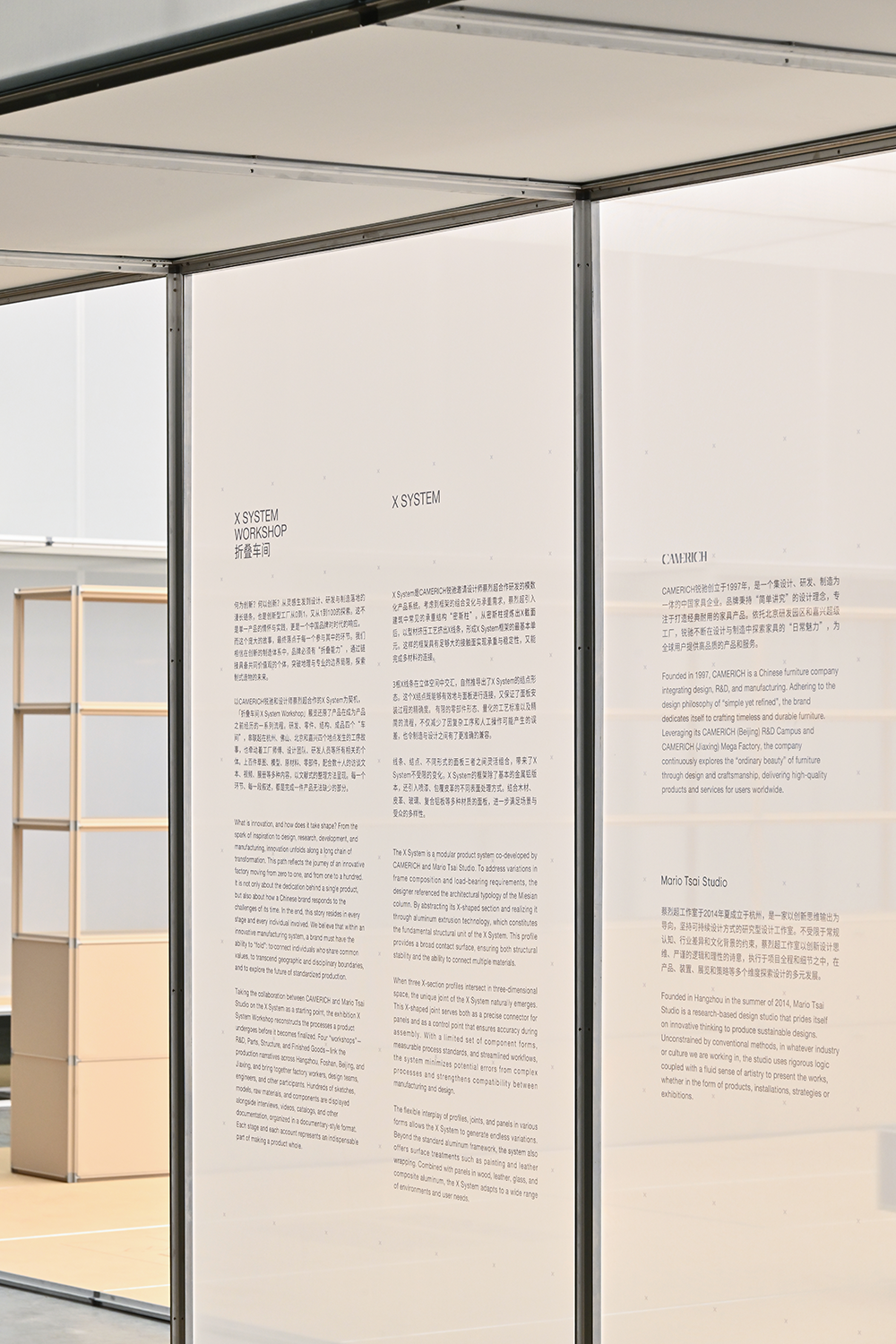

The "X System Workshop" exhibition revolves around the X System co-developed by CAMERICH and Mario Tsai. This modular product system serves as a catalyst for CAMERICH to re-examine and reorganize its R&D and manufacturing framework.

Mario Tsai Studio employs a research-oriented design approach, often posing questions based on current observations and then unpacking them from multiple dimensions. Modularity has been a long-standing topic, originating from Mario’s reflections on design and manufacturing innovation within industrial mass production. In recent years, CAMERICH has also explored how R&D could drive manufacturing innovation.

With this shared vision, the X System was born.

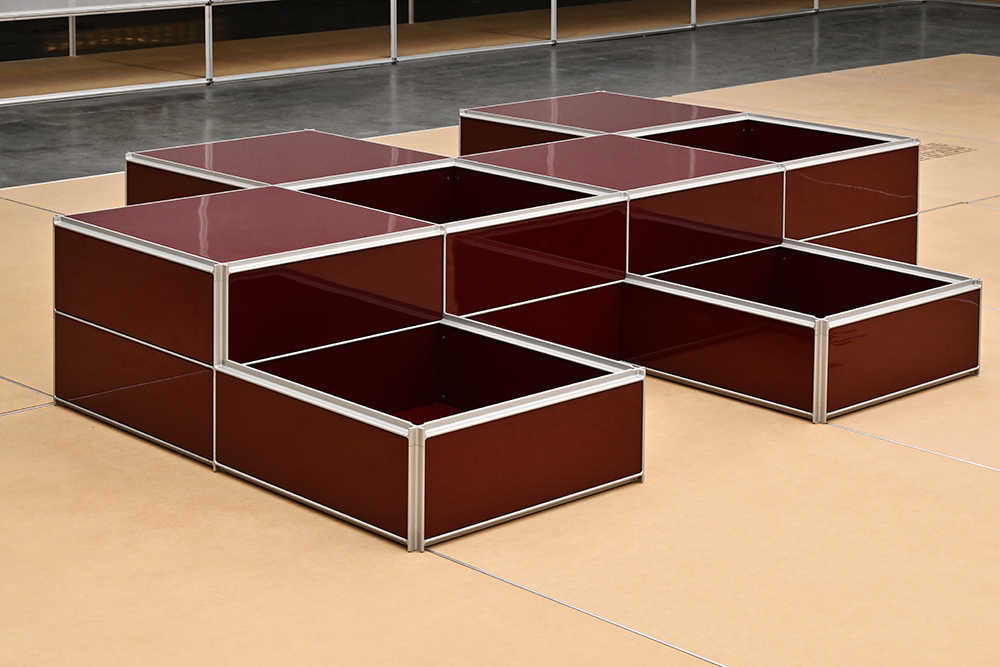

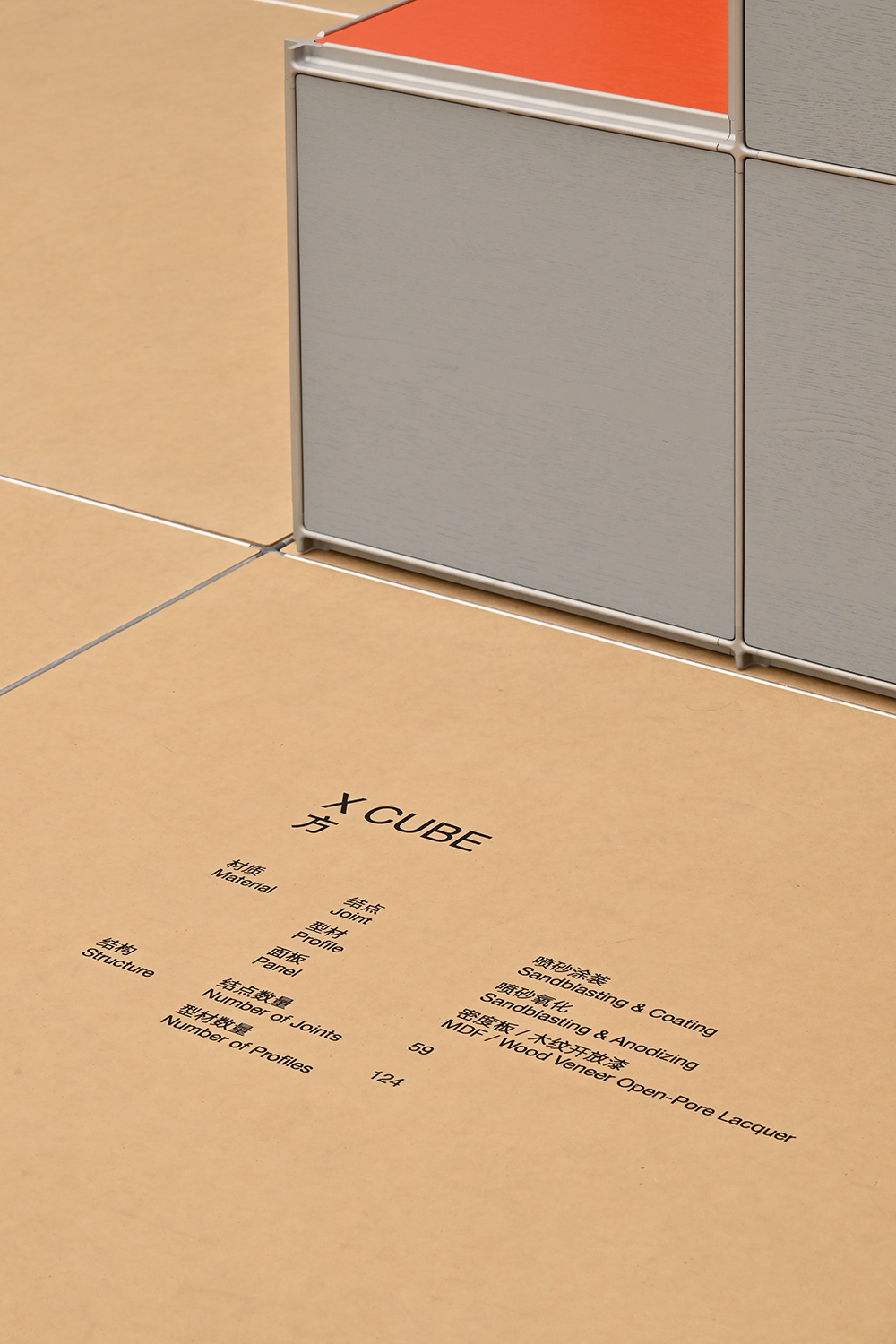

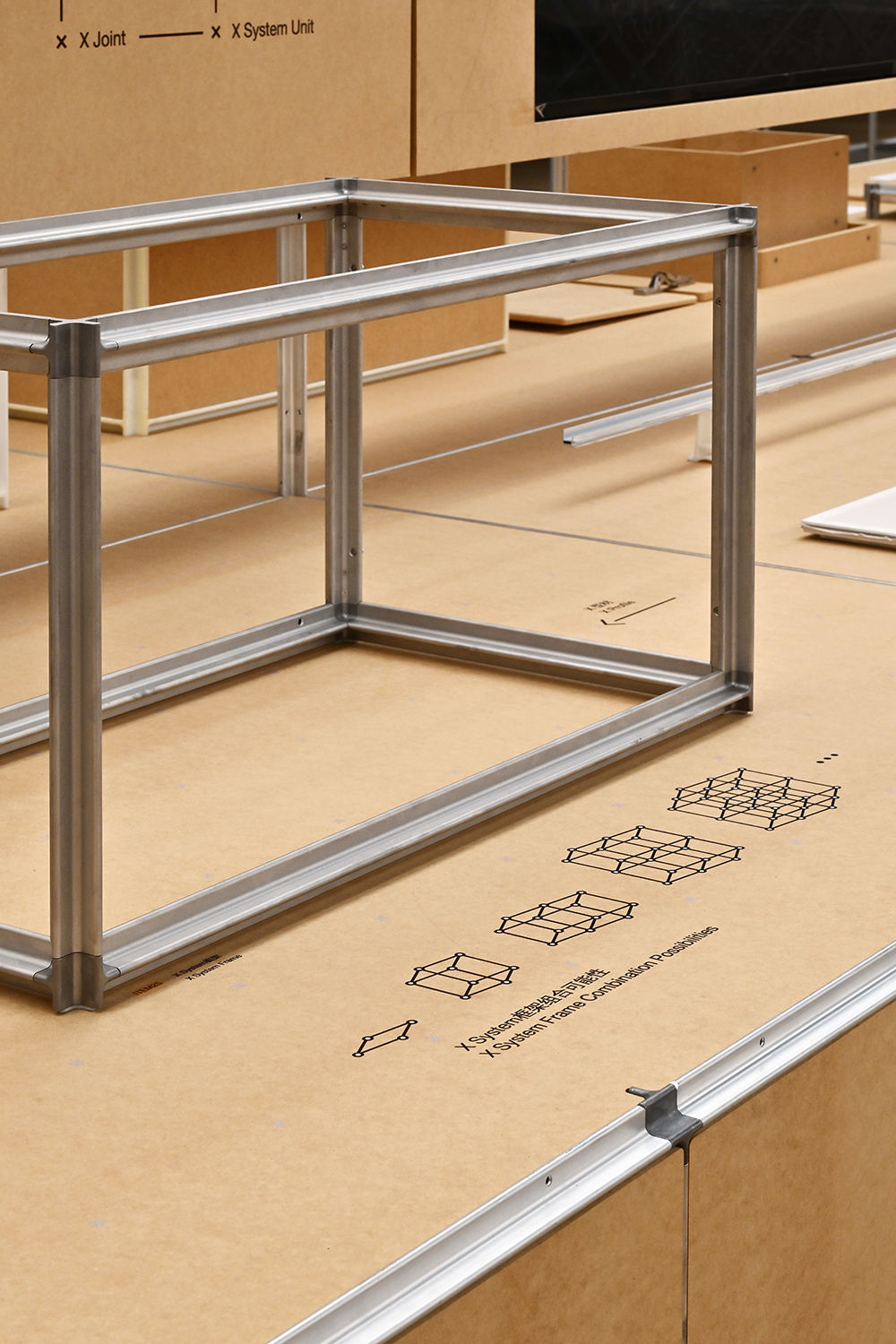

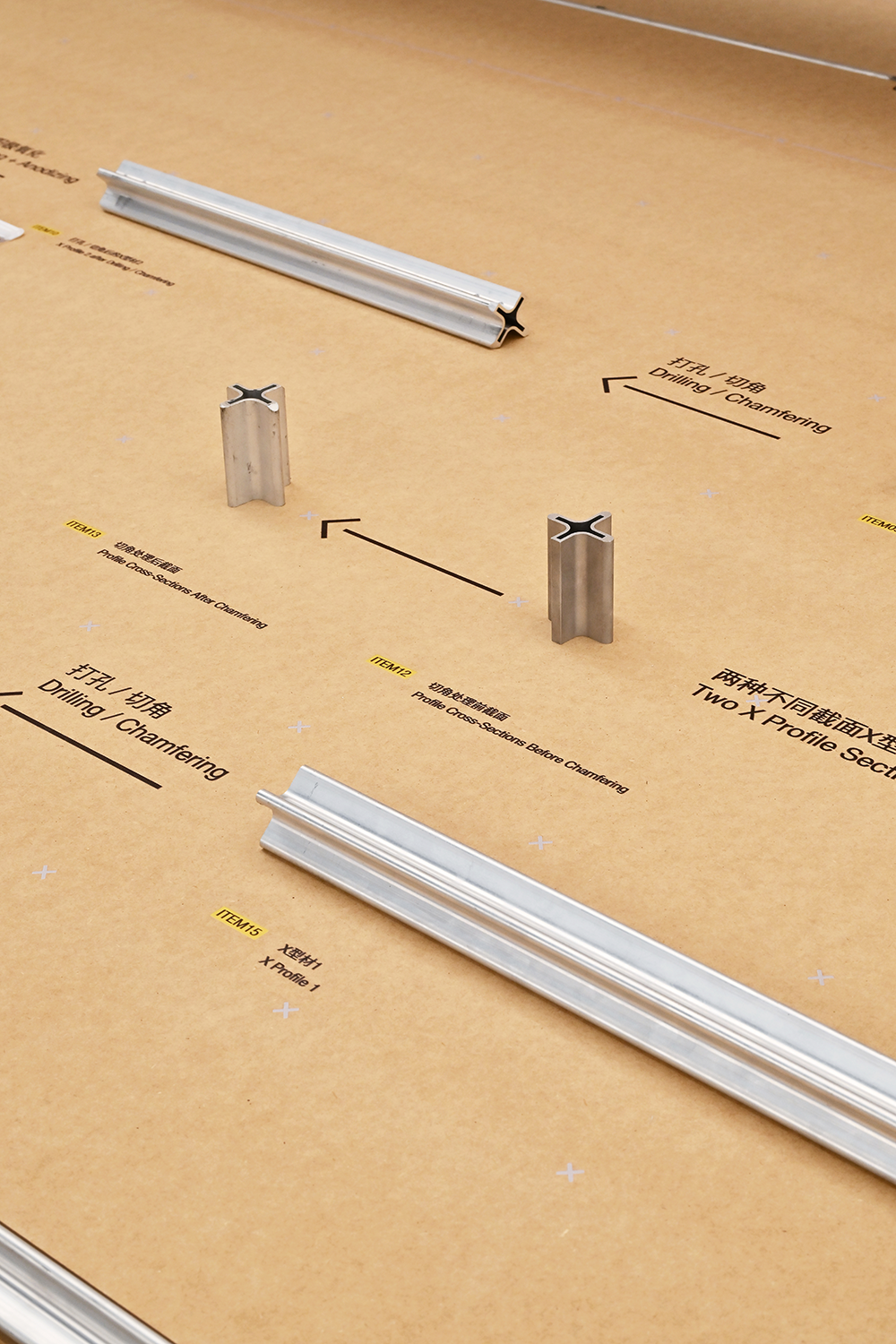

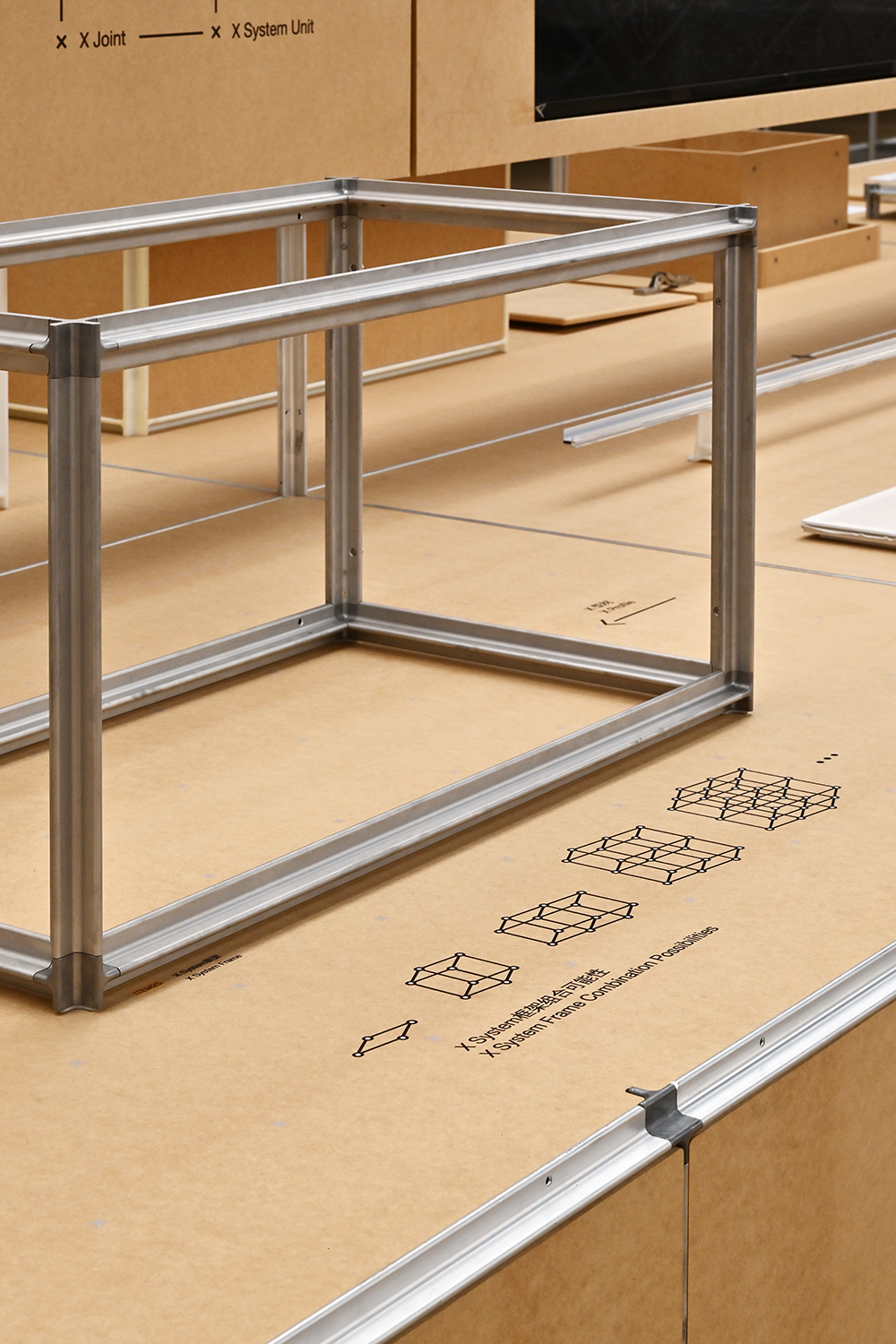

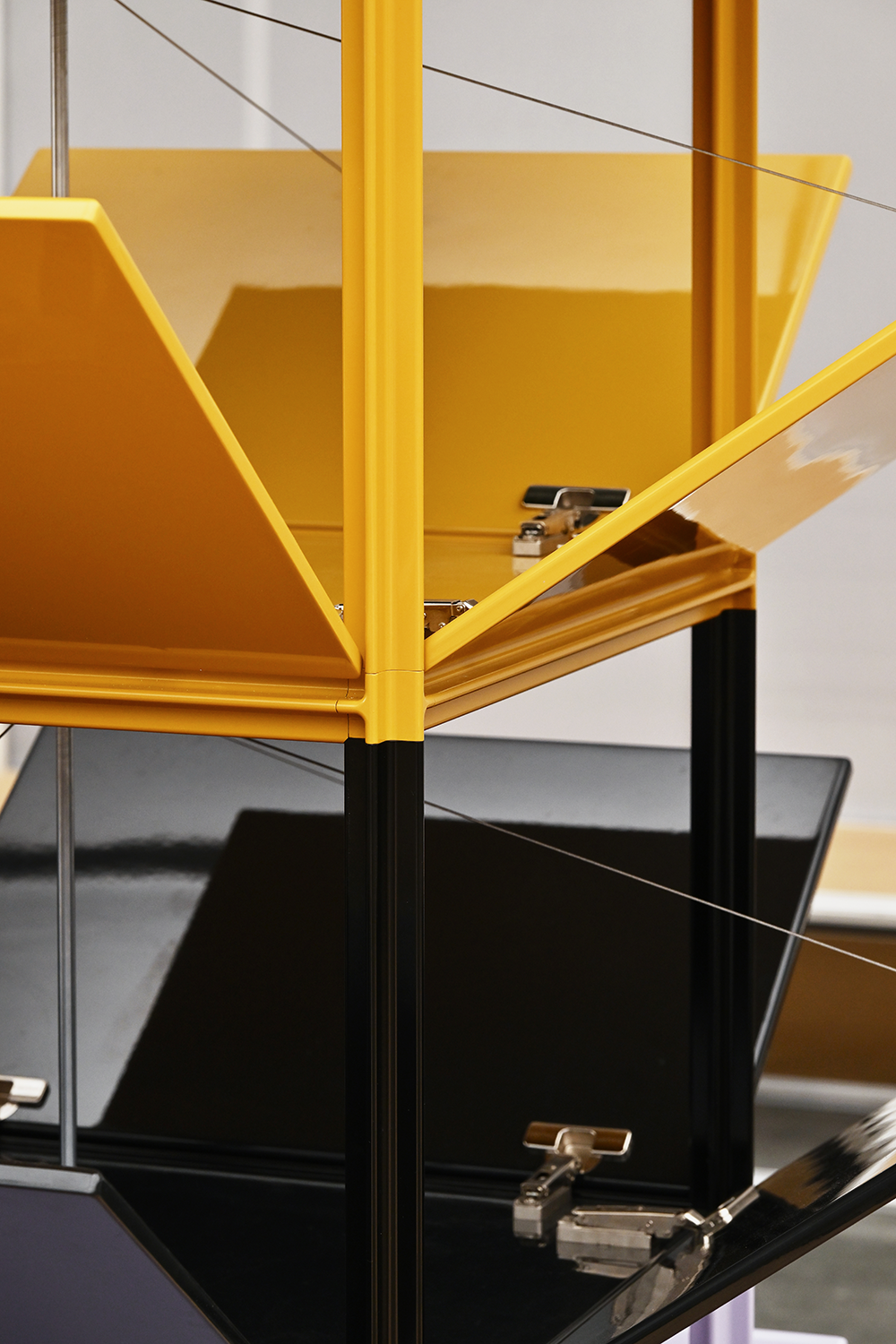

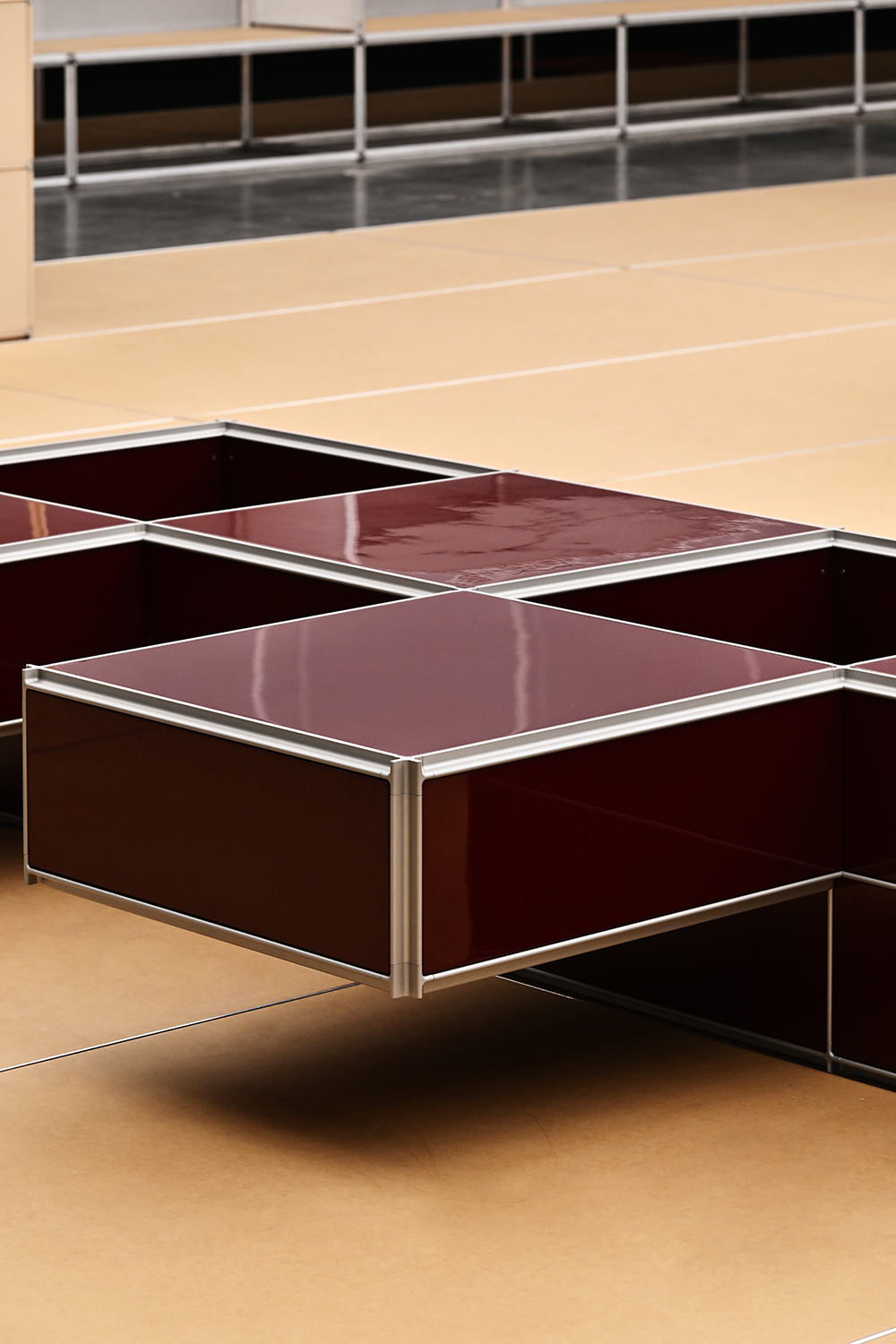

The basic modules—composed of aluminum profiles, joints, and panels—are highly adaptable and combinable with various materials and accessories to create different kinds of furniture. In manufacturing terms, the limited assortment of components, quantifiable workmanship standards, and simplified processes reduce the risk of errors caused by complex procedures or manual work, enabling more precise compatibility between design and production.

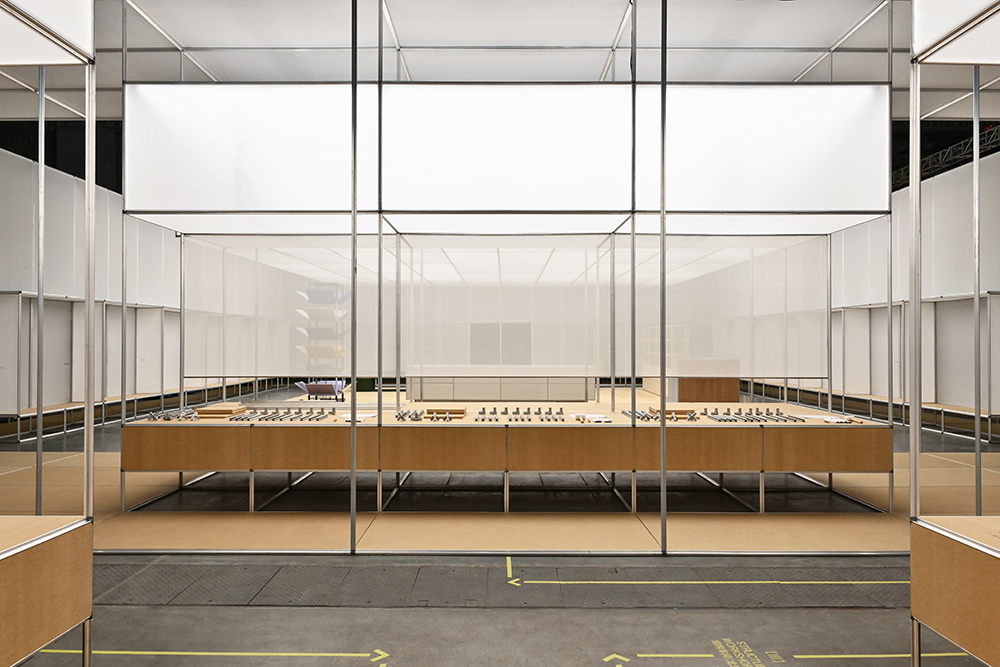

Beyond simply being furniture, X System is designed for richer possibilities. For instance, all frames, displays, and seats at this exhibition are built from X System: 1,511 Joints, 3,219 profiles, 441 MDF boards—all of which can be recycled and reused after the event, continuing CAMERICH’s commitment to sustainable exhibitions.

X system Workshop: from R&D to Manufacturing

An Organic Ecosystem

A product’s journey from inspiration to design, R&D, and manufacturing is a long chain involving various regions, production steps, and people participating in it—each part being crucial. CAMERICH believes that innovative manufacturing requires the "folding capability" to connect like-minded individuals, break geographical and disciplinary limits, and explore the future of standardized making. The X system Workshop exhibition was conceived with this in mind.

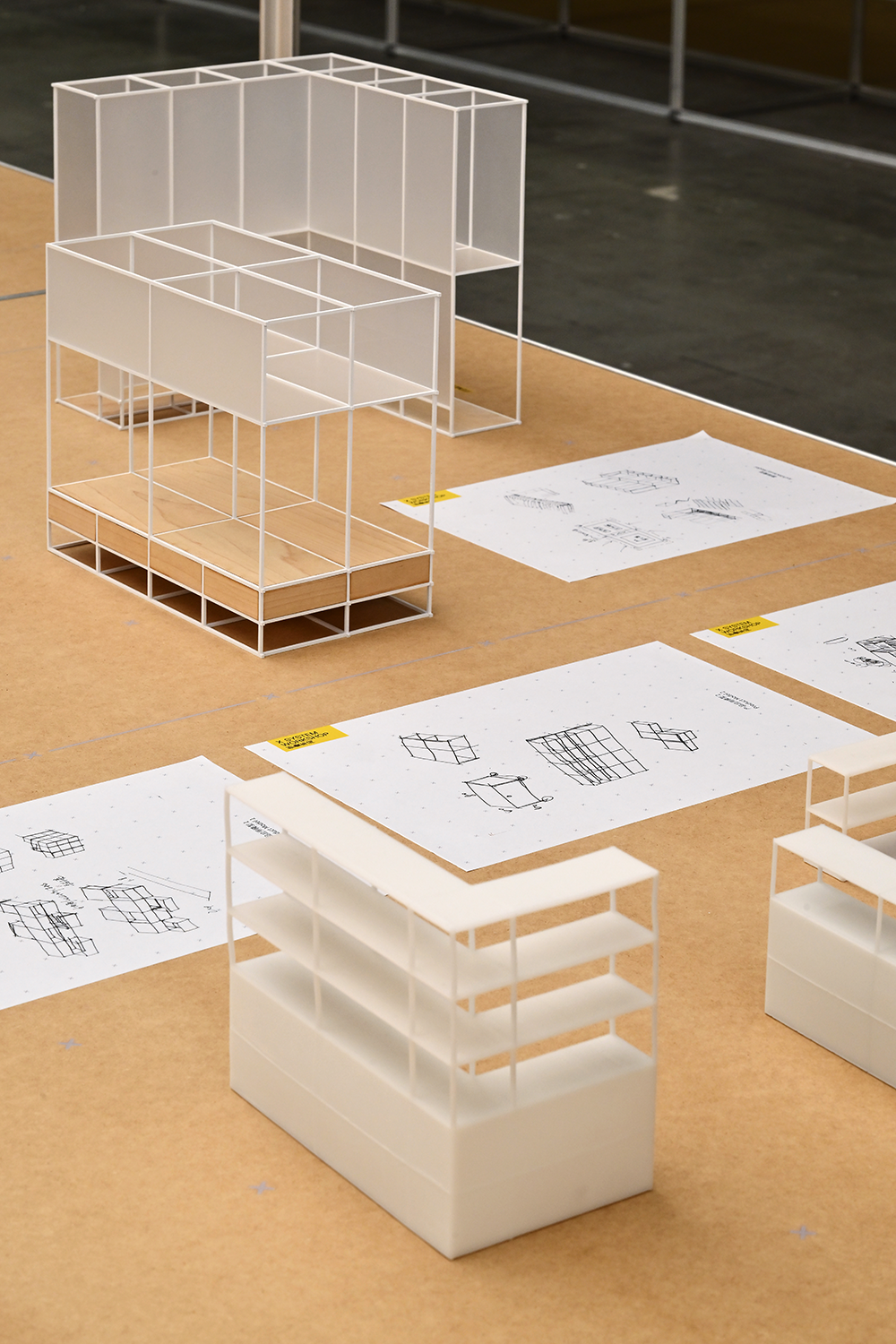

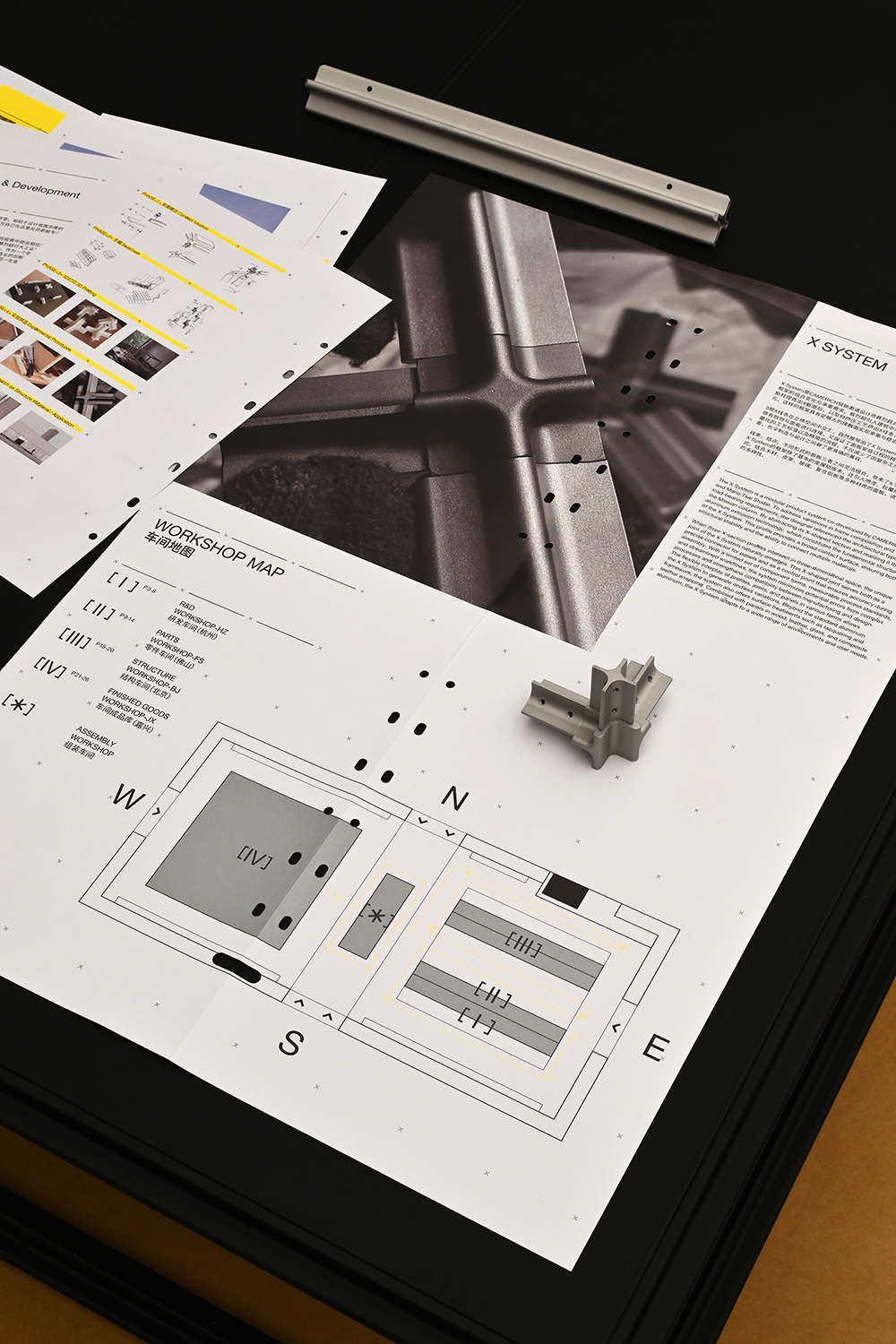

The exhibition uses the development of the X System as an example, reconstructing the series of processes a product undergoes before becoming a finished piece. The exhibition features models, sketches, raw materials, and prototypes from the X System’s R&D process, meticulously detailing each stage from development through implementation and production.

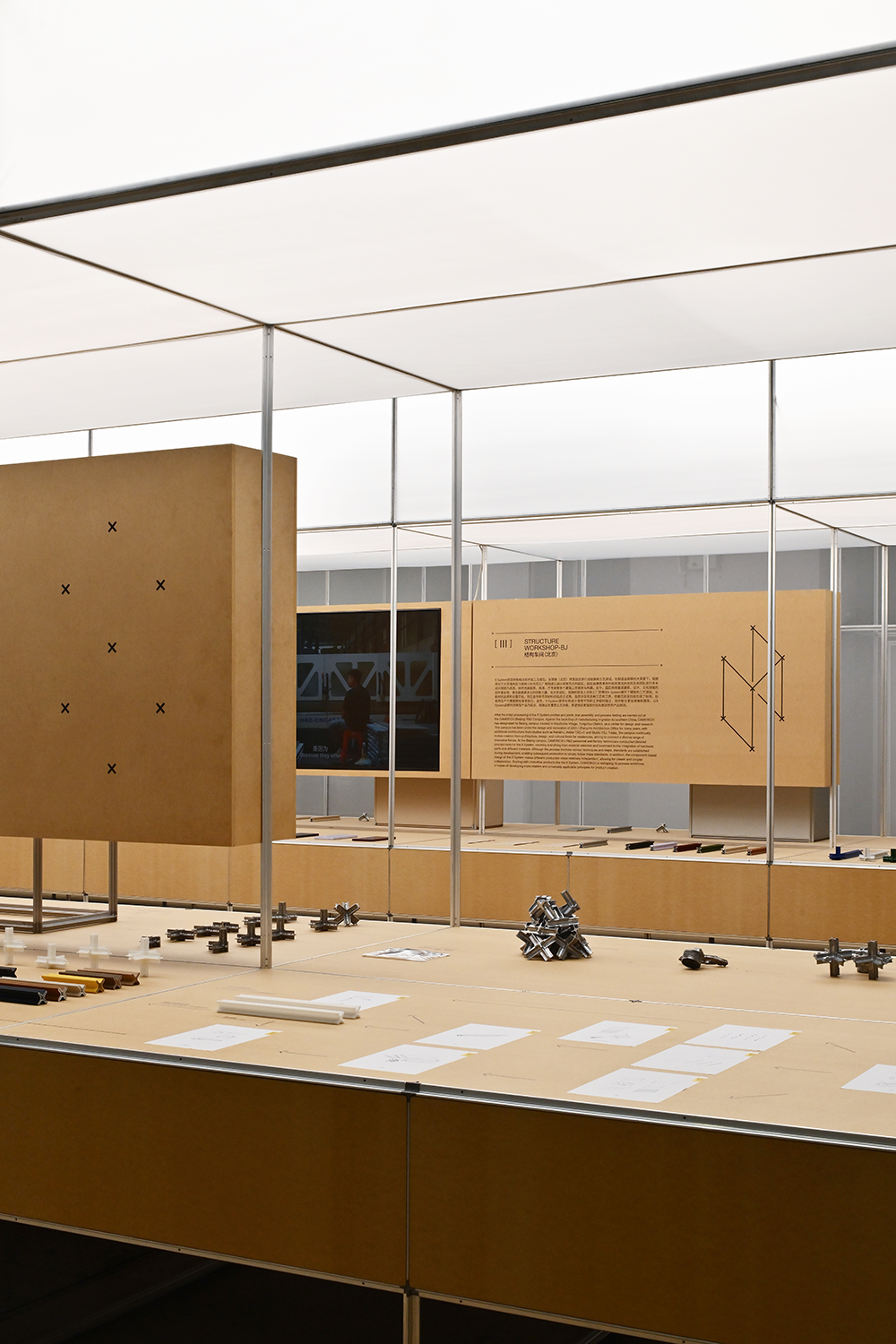

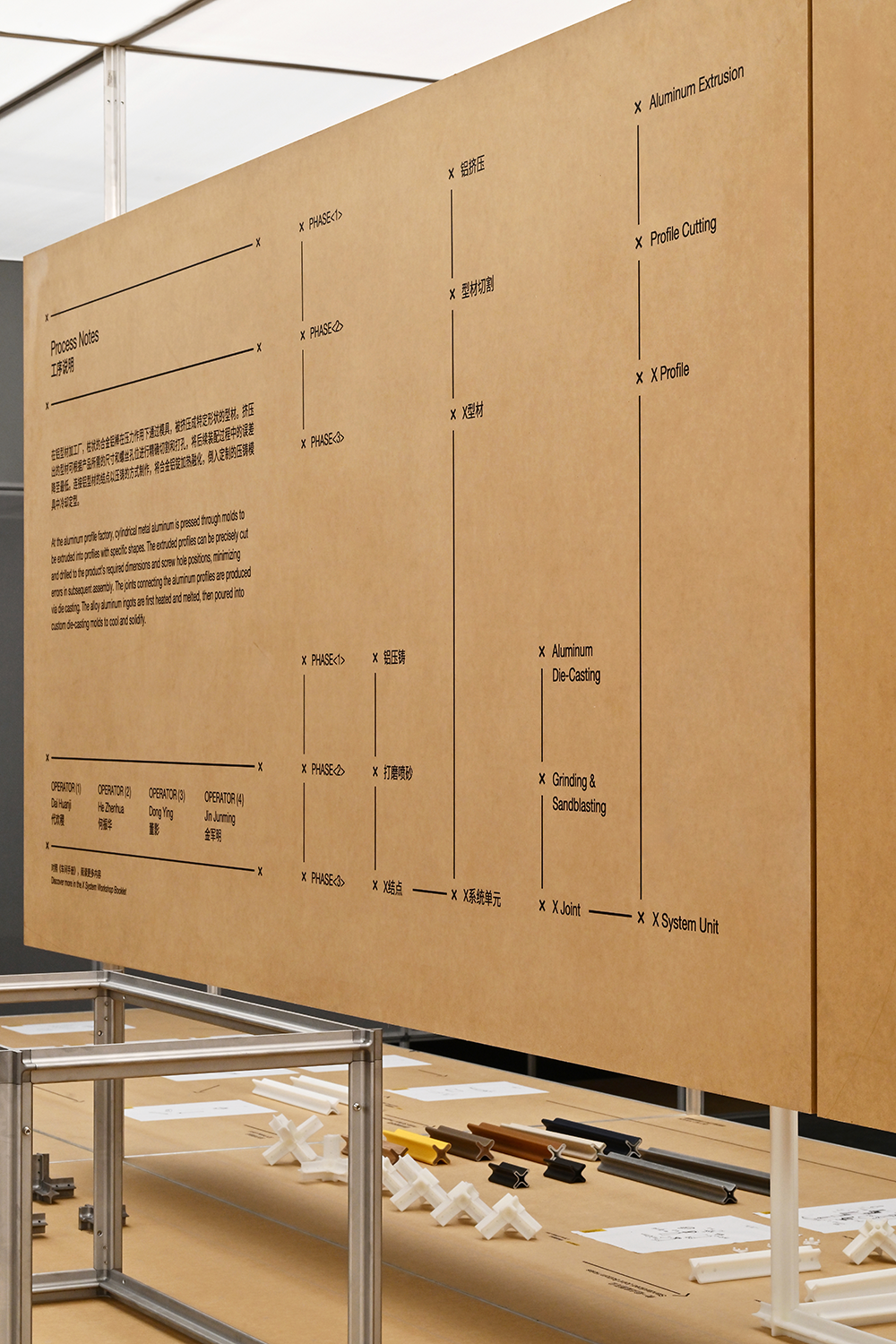

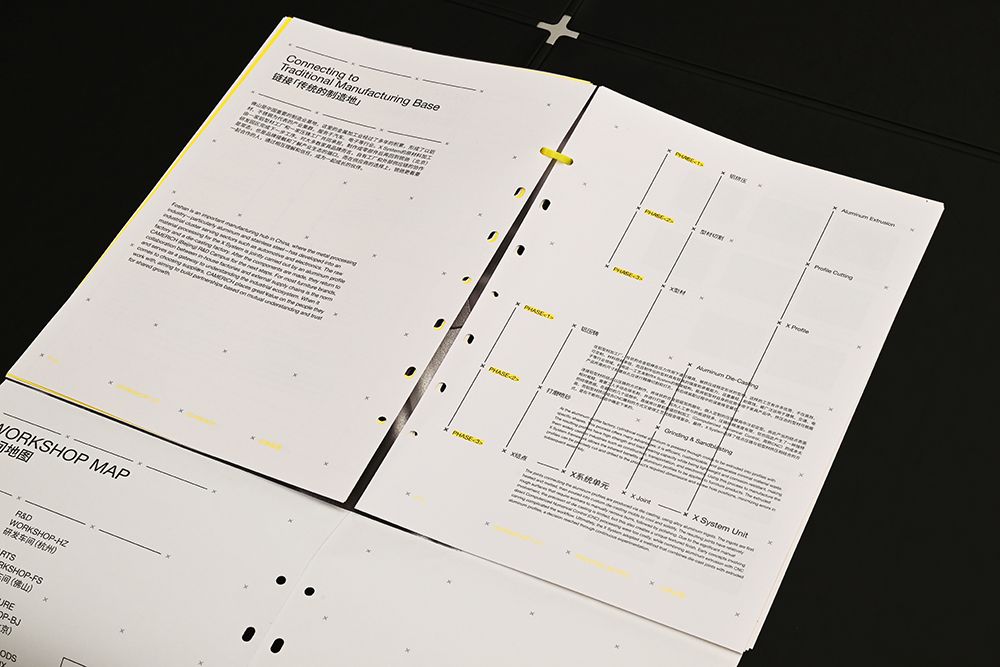

Hangzhou, Foshan, Beijing, and Jiaxing have been designated as the "R&D Workshop," "Components Workshop," "Structure Workshop," and "Finished Product Workshop," respectively, each accompanied by unique visuals and exhibition texts. Combined with interviews from the "Workshop Manual" available on-site, visitors can deeply understand how various individuals engaged in R&D and production across four locations contribute to an organic ecosystem through one product.

R&D, Components, Structure, Finished Products,

Restoring the Authentic R&D and Production Chain

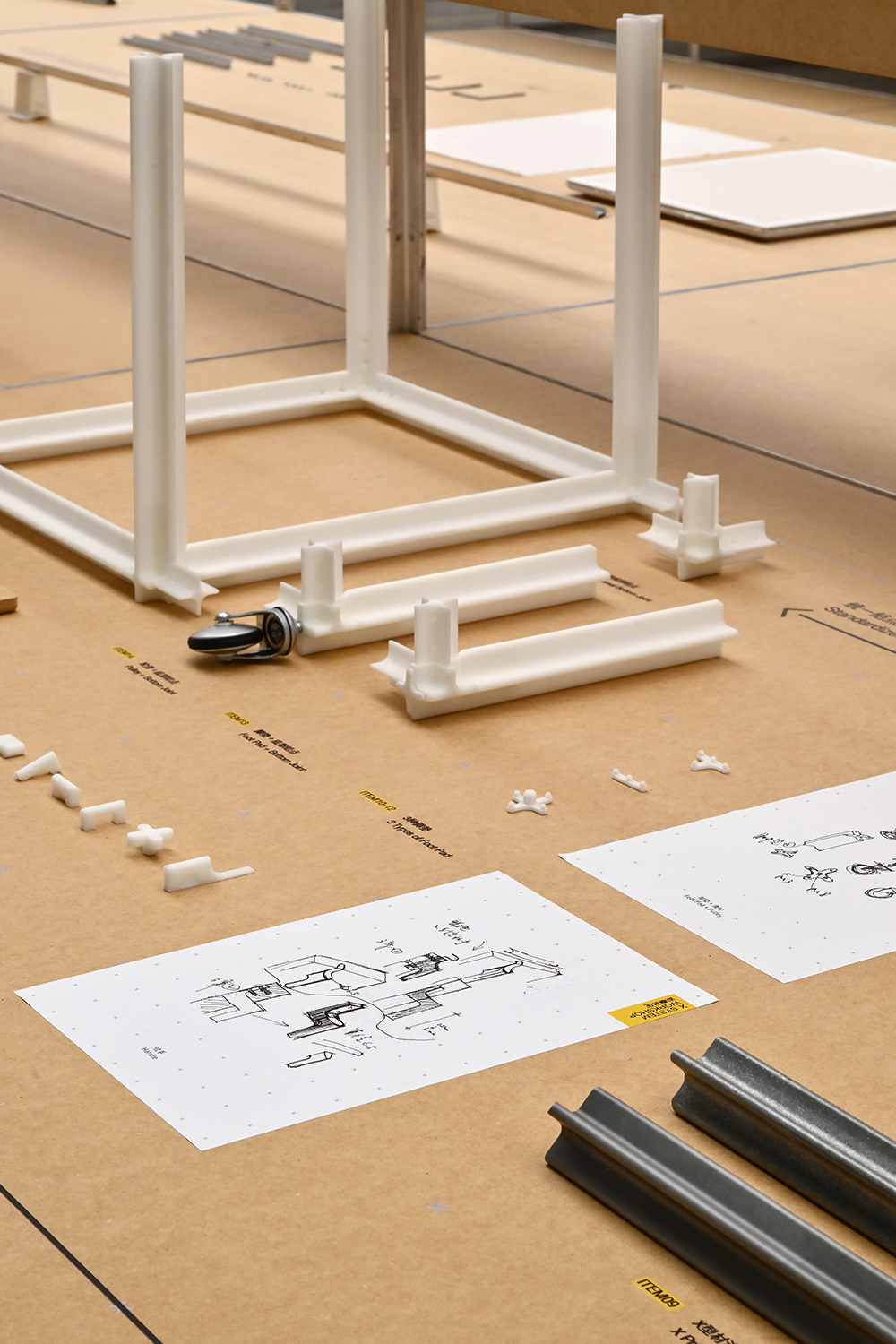

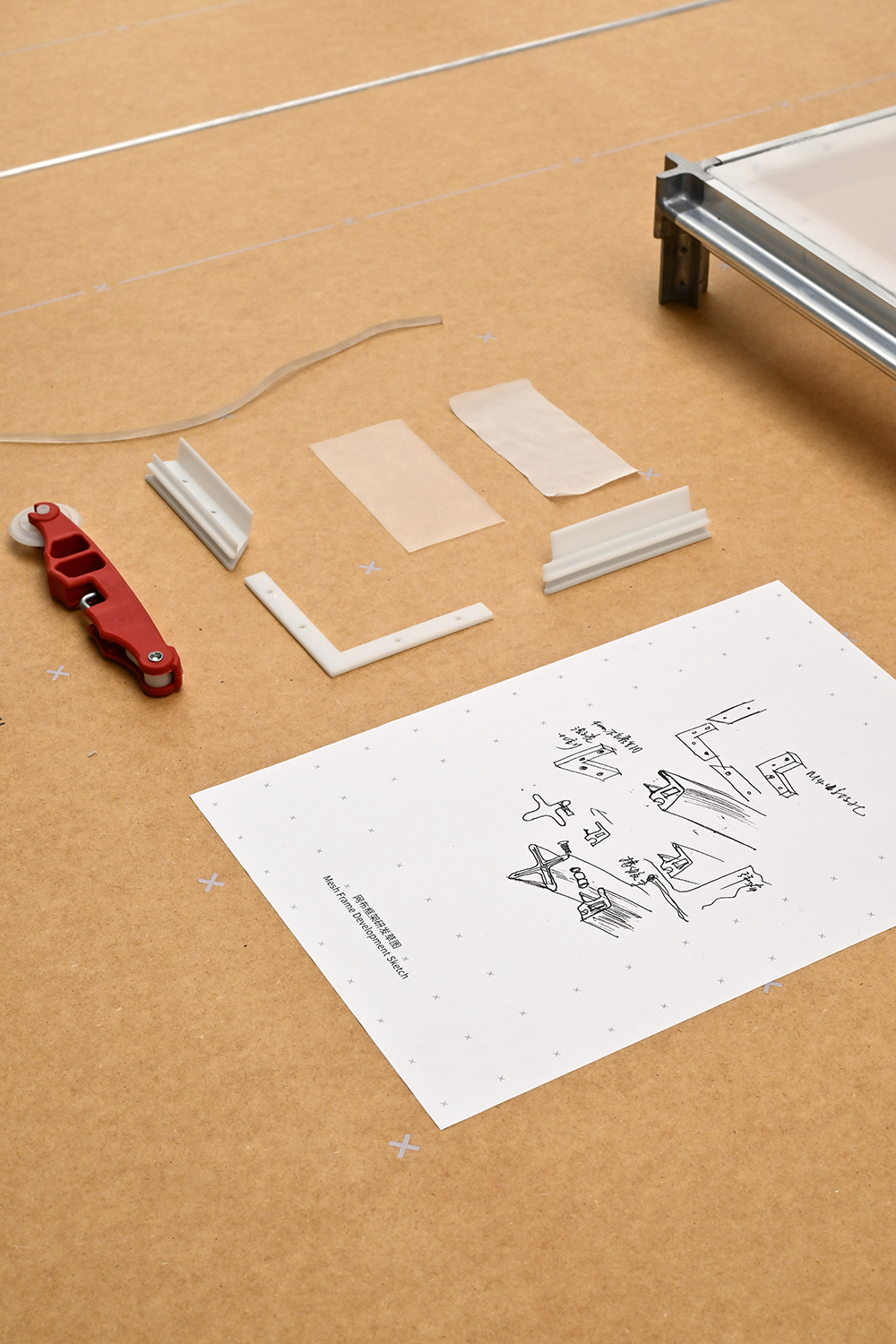

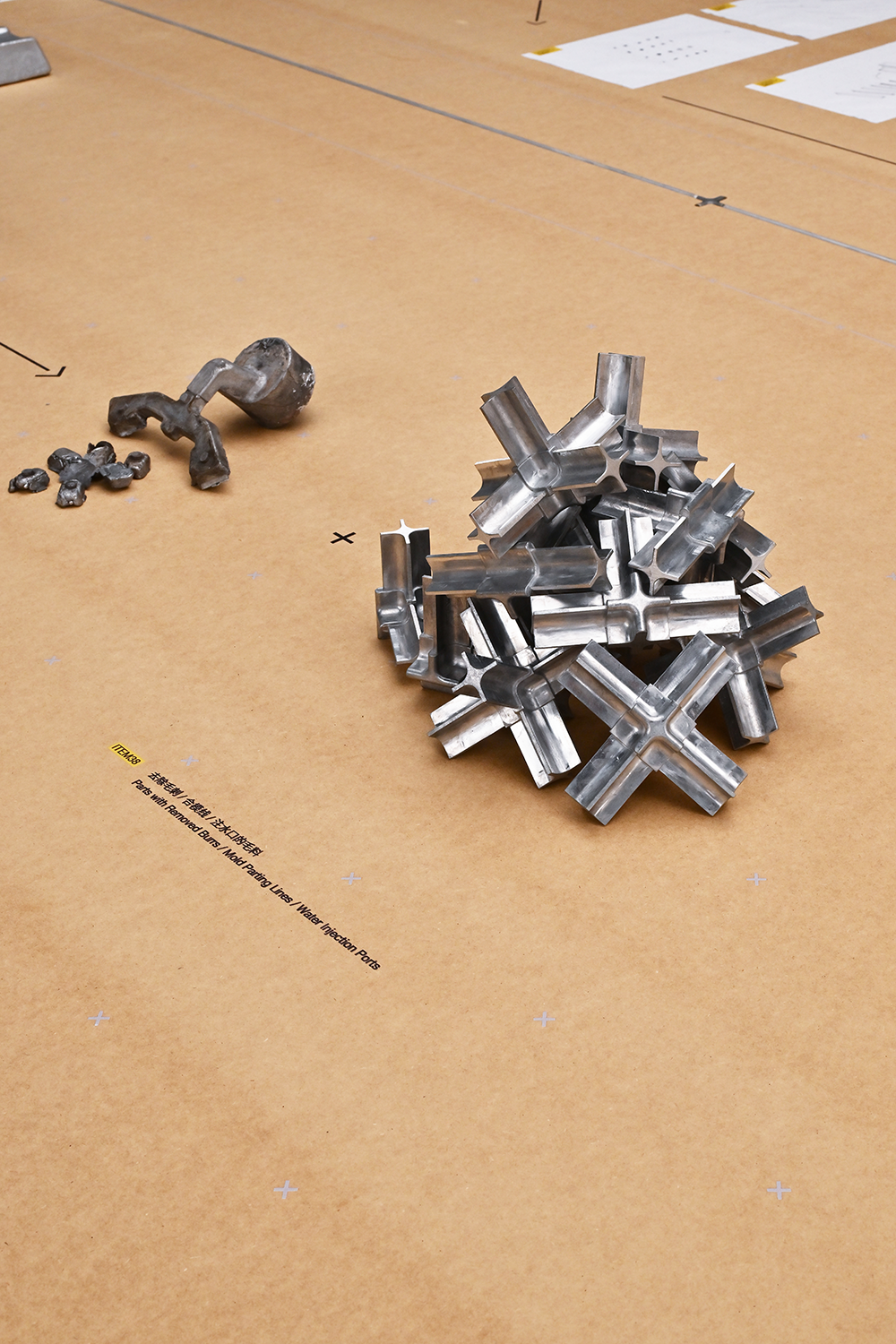

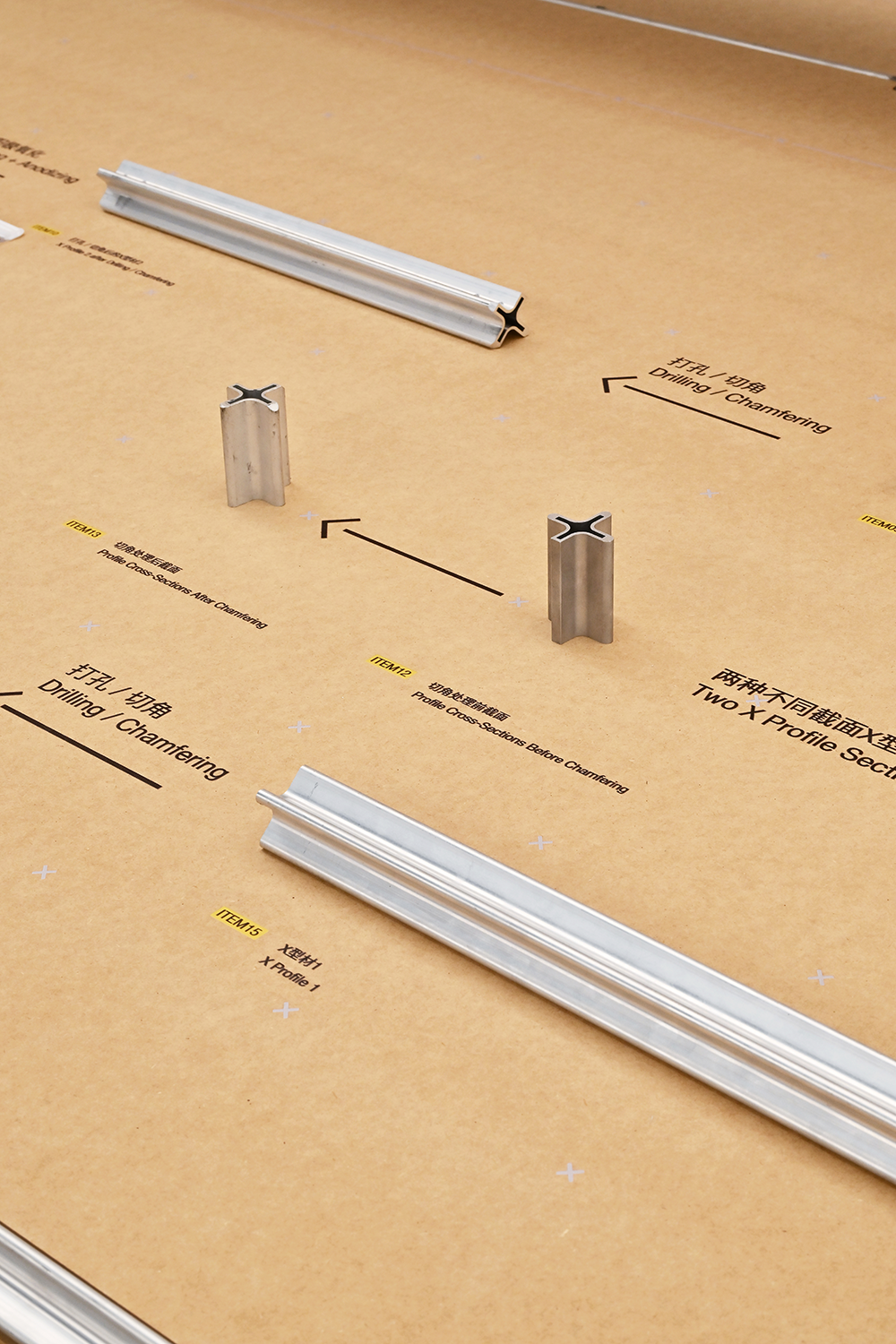

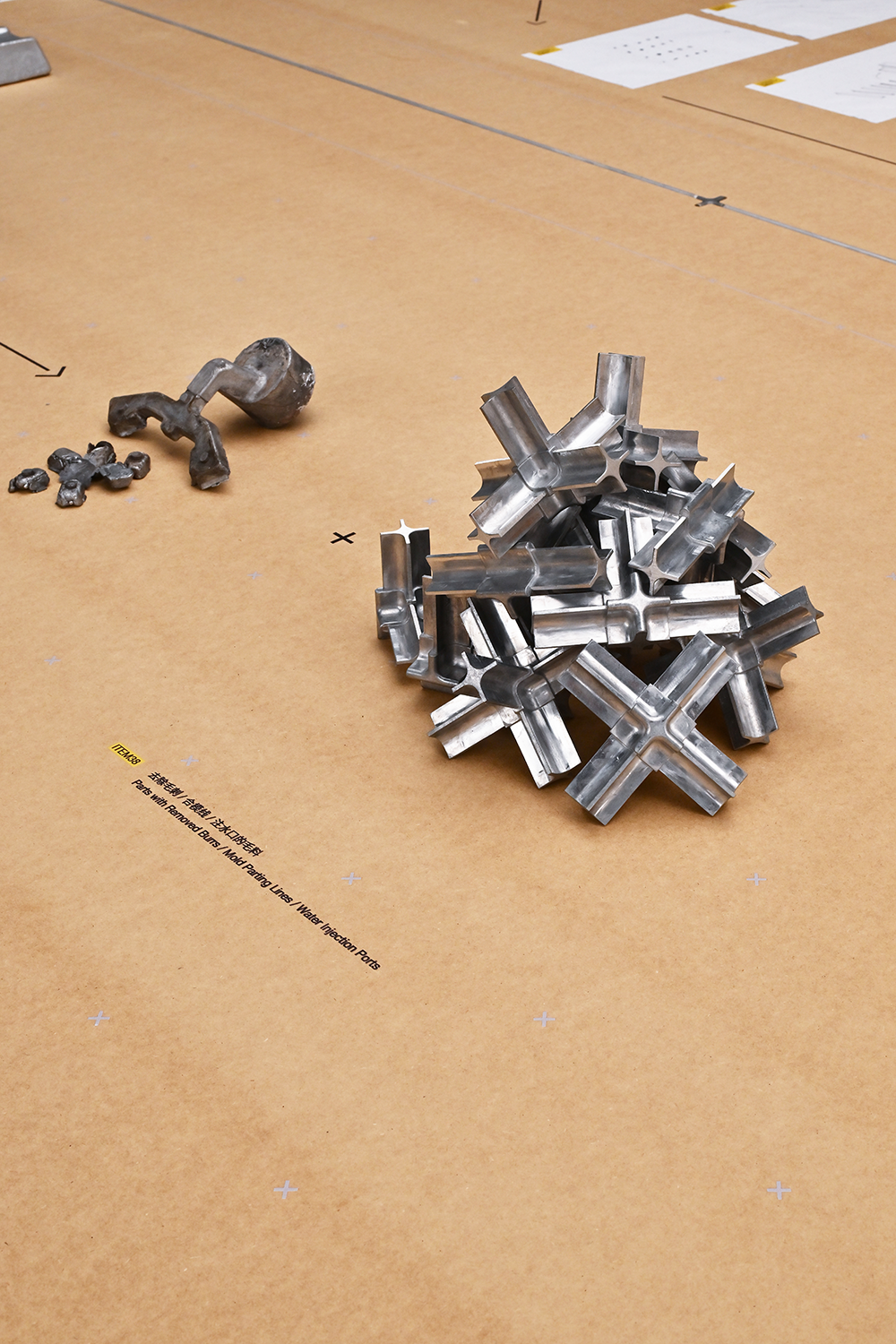

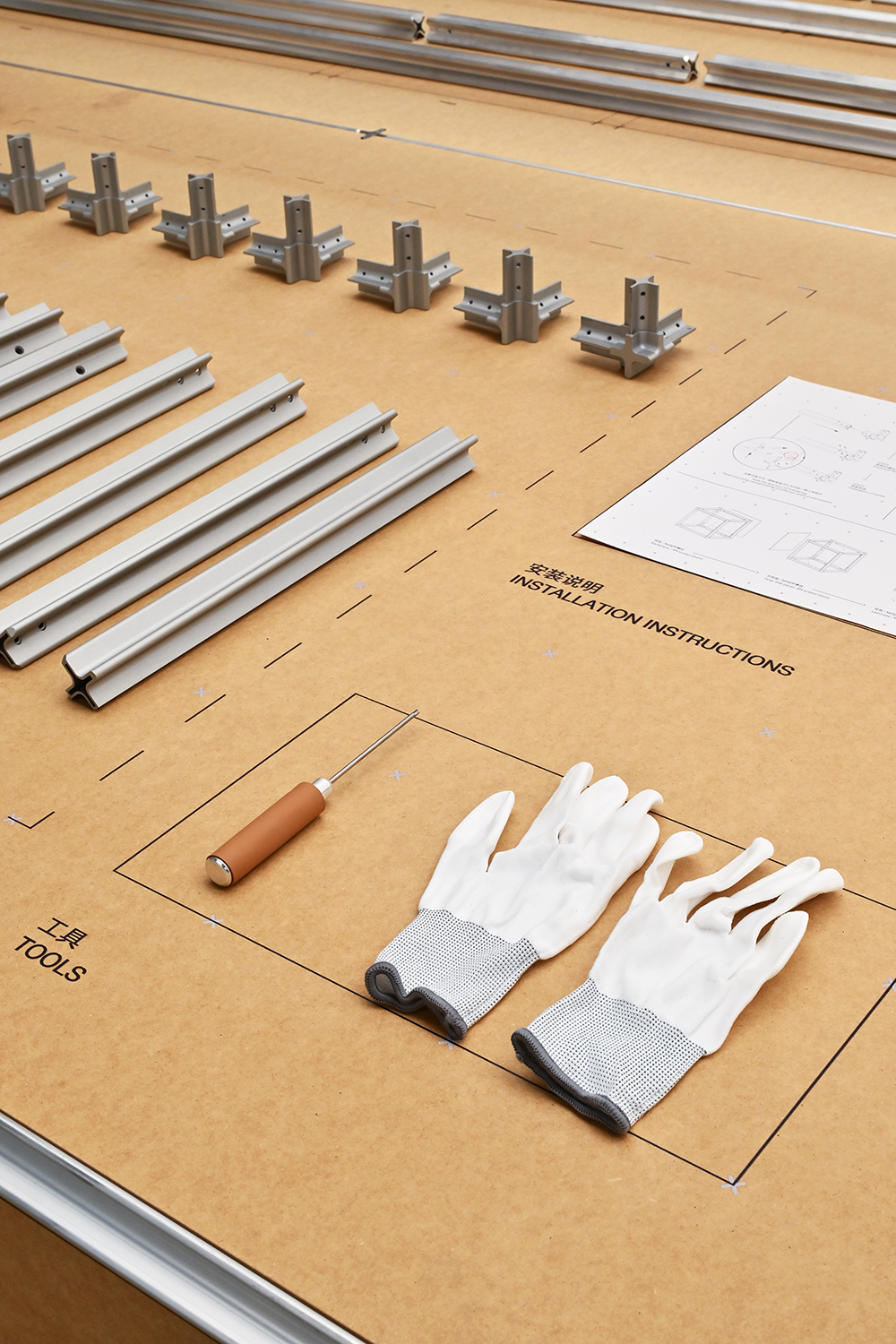

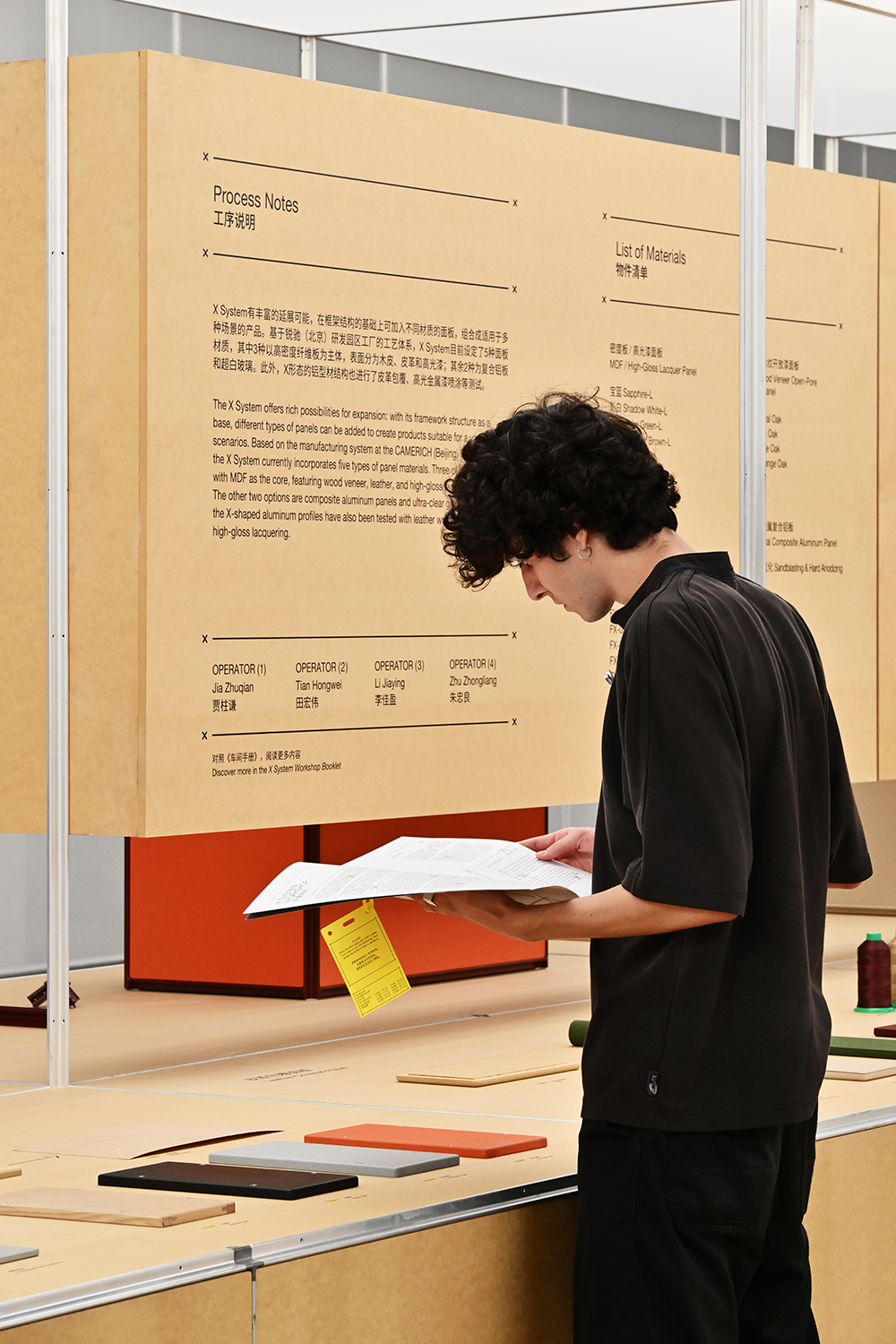

The X system Workshop exhibition, organized around the “workshop” concept, visually presents the R&D and manufacturing processes of the X System. Hundreds of physical items are on display, including conceptual drawings, sketches, 3D prints, raw materials, molds, components with different finishes, and final product samples.

In the Hangzhou “R&D Workshop,” visitors see how the X System concept took shape. Inspired by the "Miesian column" commonly in architecture, Mario designed the X-profile. Three intersecting X-profiles in 3D space led naturally to the form of the connecting node. After solidifying the design, Mario’s team began researching structure, materials, and application models.

In the Foshan “Components Workshop,” aluminum alloys are processed into X-profiles and X-Joints. The X-profile uses aluminum extrusion, conferring high strength and load-bearing capacity. Profiles can be precisely cut and drilled to specification. X-Joints are made by die casting and finished with sanding and shot-blasting for unique surface texture.

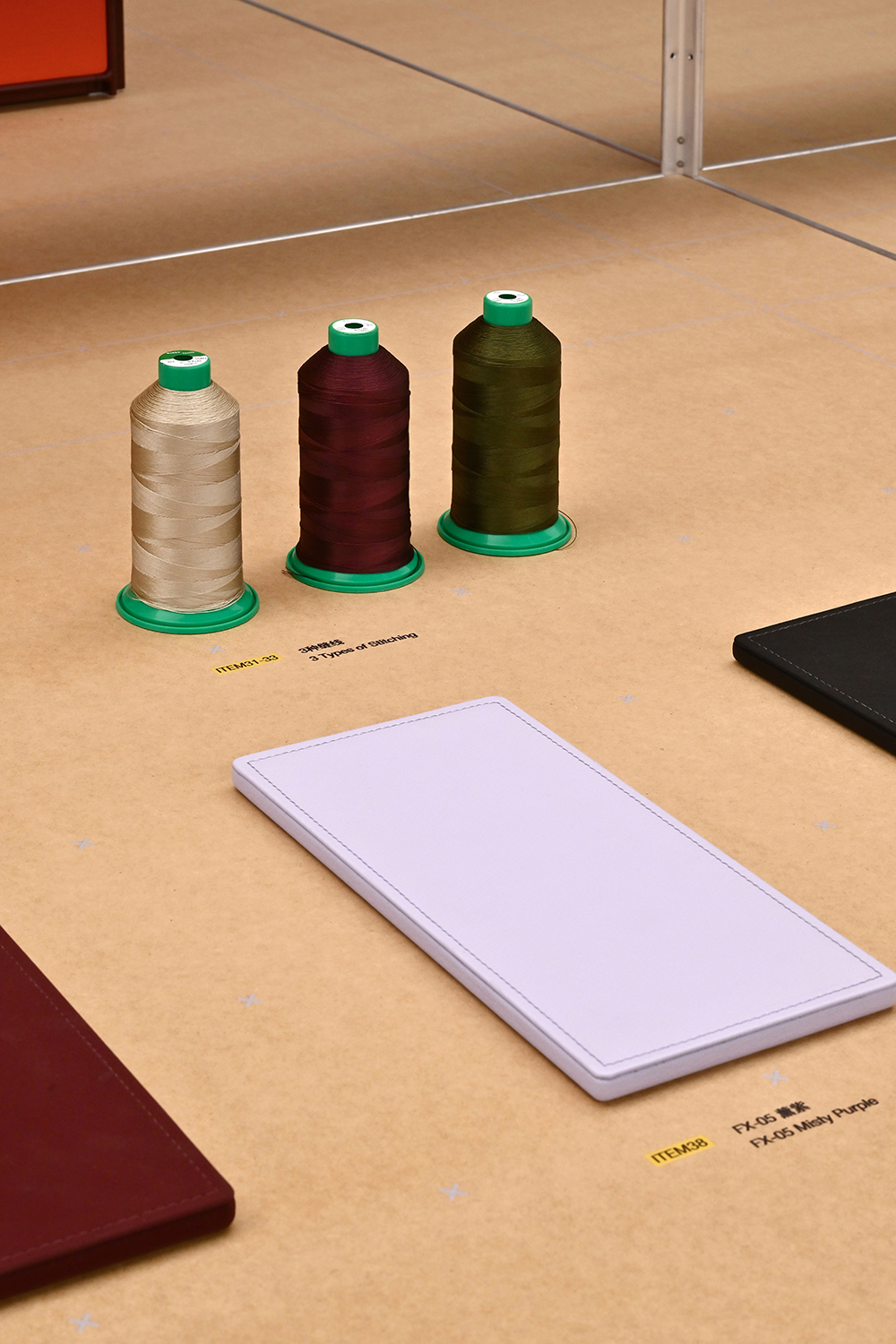

At the Beijing “Structure Workshop,” CAMERICH’s R&D team focused on the development of panels and hardware, as well as finishing processes, and assembly tests. On the X System frame, different panels and accessories can be added, creating products for a variety of scenarios.

The Jiaxing "Finished Product Workshop" displays X System 1.0 prototypes—sideboards, coffee tables, bookshelves, and experimental pieces demonstrating the product’s versatility. Future developments will focus on new materials, surface treatments, modular partitions, large-scale display racks, and a refined customization system.

Outside the four core workshops, there is an "Assembly Workshop" for live demonstrations of basic unit assembly. Visitors can participate, bringing people closer to the product. The other side of the assembly station explores X System’s sustainable design—through recycling and processing, materials and components may be reused in furniture and exhibitions.

Exhibition Statement, Manual, Video

Front-stage and Back-stage Design

To better articulate and document the process, magazine into planned and designed the “Workshop Manual” for the exhibition. Staying true to the workshop concept, the manual records the development and manufacturing steps at the four sites, incorporating interviews with 16 designers, suppliers, factory workers, and R&D participants to form a detailed textual and visual archive.

The manual, used in conjunction with on-site navigation, helps visitors understand the workflow and design thinking of each workshop. After the exhibition, it serves as a standalone resource covering the R&D process, collaboration models, and cultural values of X System—a vital reference to understand CAMERICH’s innovation and vision in standardized production.

Simultaneously, magazine into and Xinqiao Films co-produced a documentary about the X System, also shown on site. The film captures the flow of products through different R&D and manufacturing stages, interwoven with designer's narration, bringing out the regional, human, and cultural depth.

In the X system workshops

many unexpected surprises

The curatorial team of CAMERICH, Mario Tsai Studio, and magazine into intentionally made the workshop expressive, interactive, and lively. Throughout the evolving exhibition, the teams added many engaging touches:

① The exhibition uses a workshop trolley built with X System to distribute the manuals elsewhere inside the workshop.

② The mesh fabric used in the booth is the same type as used in Mario Tsai Studio's "Soft Power" design project.

③ To make the workshop livelier, magazine into hid over 20 real factory slogans near the seating area, presented as "sticker ads".

④ Souvenirs were made from leftover and scrap X-profile material.

CURATORS

Mario Tsai Studio

Product Design / Spatial and Content Curation

Founded in Hangzhou in the summer of 2014, Mario Tsai Studio is a research-based practice that prides itself on innovative thinking to produce sustainable design. Unconstrained by conventional methods, the practice works in any industry or culture it works in, the studio uses rigorous logic coupled with a fluid sense of artistry to present the works, whether in the form of products, installations, strategies or exhibitions.

subfictions (magazine into)

Content Curation and Visual Narrative / Workshop Manual Design

into (subfictions) was founded in March 2018 in Xiamen. As a creative team with a long-standing focus on design and culture, into follows the principle of content-driven design, transforming research findings from interviews and investigations into brand communication, visual systems, publications, exhibitions, and other diverse media. At the same time, it operates the publishing project magazine into, offering a long-term, authentic, and objective perspective on design and cultural research, extending into books, exhibitions, derivatives, and collaborative projects.

Xinqiao Films

Documentary video production

A personal creative studio founded by Xinqiao, engaged in ongoing collaborations with brands and institutions spanning art, design, architecture, and fashion. The practice involves observing not just the subject, but also the surrounding context—the environment, objects, and fleeting moments—attuned to authentic experiences and emotions. Within a space of intentional constraints, his work remains distinctly personal.